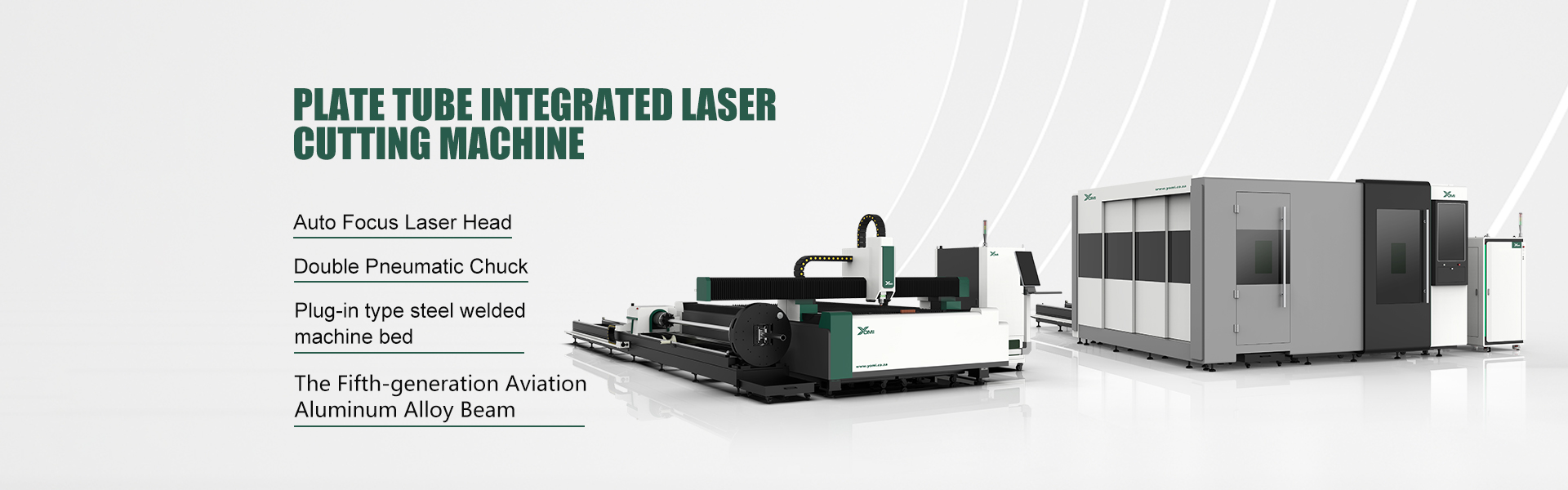

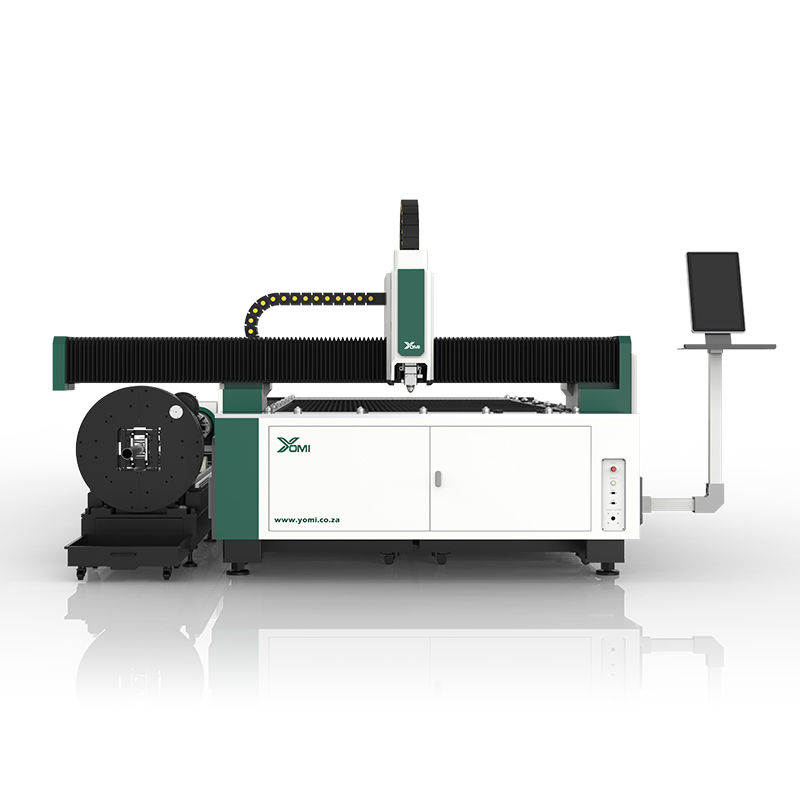

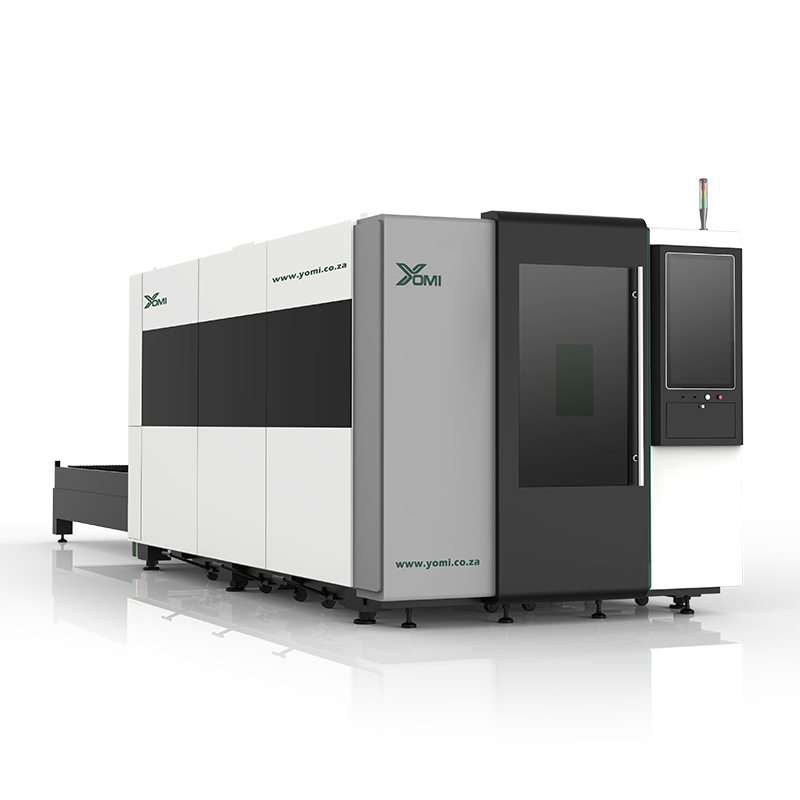

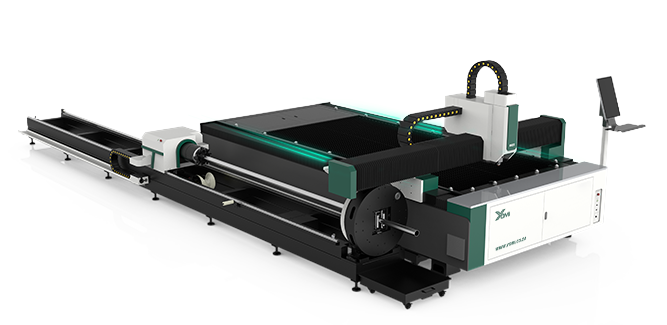

Dual-use Sheet&Tube Fiber Laser Cutting Machine

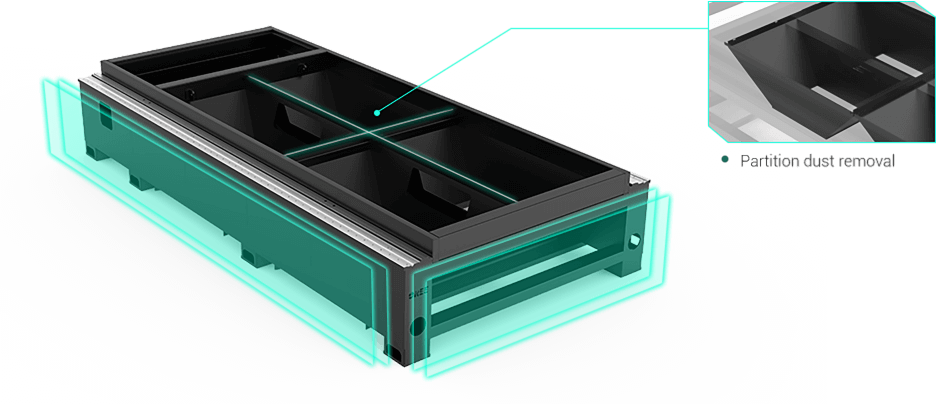

Superheavy Steel Welding Machine Bed

The bed adopts 12mm super-thick monolithic steel plate laser blanking.The groove welding method is used to make the plates reach equal strength butt Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the extremely high stability and cutting accuracy of the bed.

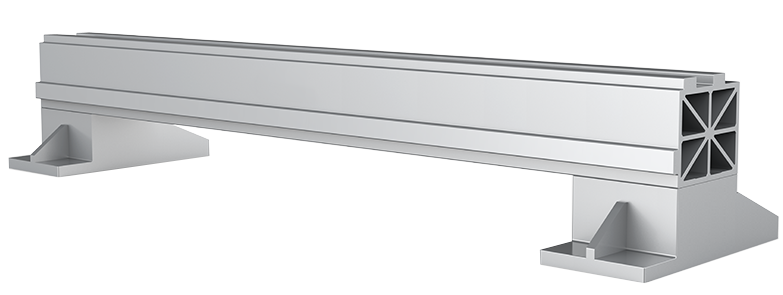

The Fifth-generation Aviation Aluminum Alloy Beam

The whole beam is processed by T6 heat treatment process to make the beam obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

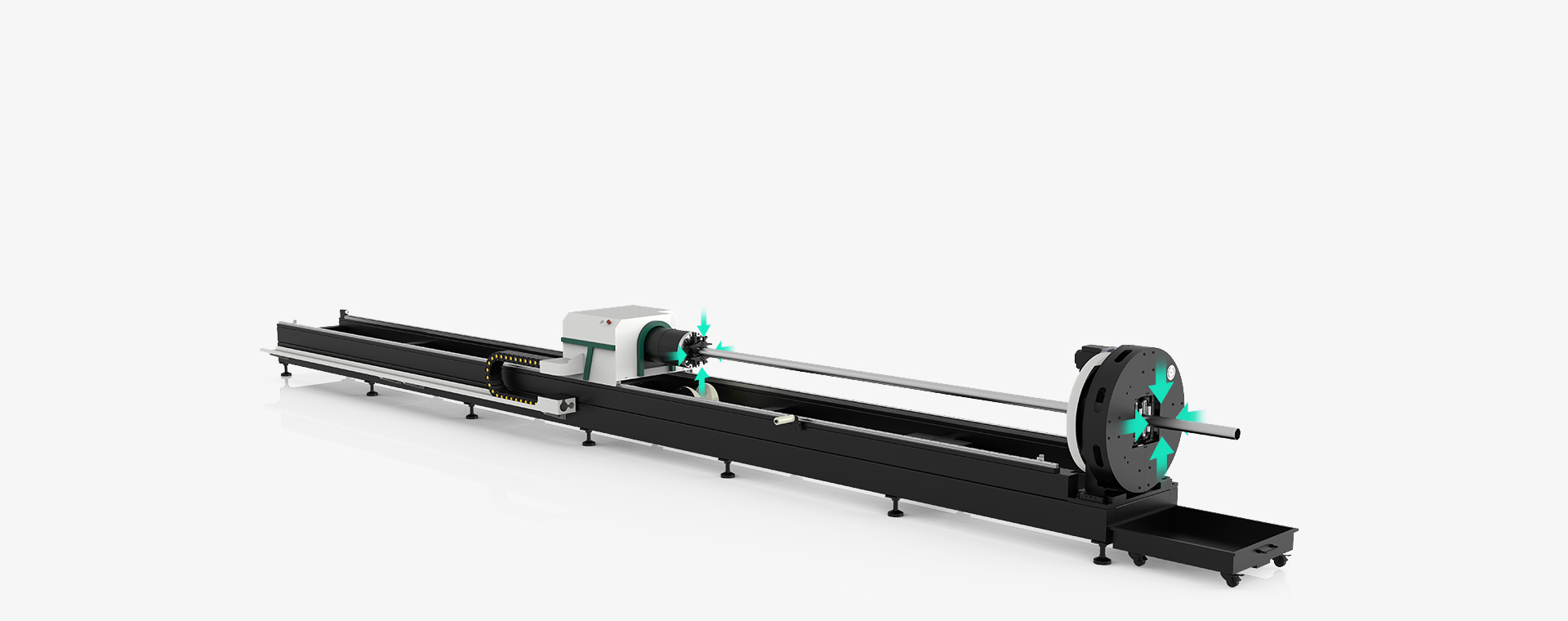

Double Pneumatic Chucks

The two-way pneumatic chuck tube automatically locates the center, extends the transmission structure to improve stable operation, and increases the jaws to save materials.

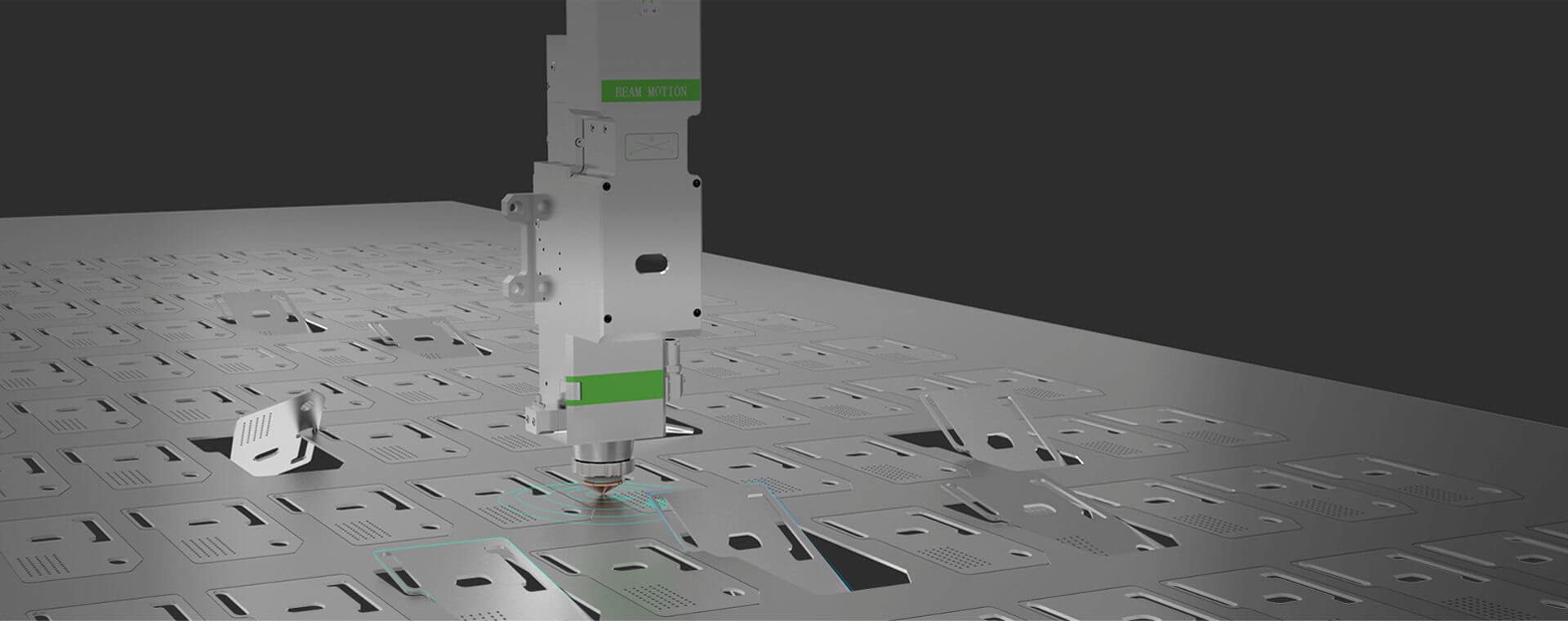

Auto Focus Laser Head

Suitable for a variety of focal lengths, the focus position can be adjusted according to different thicknesses. Flexible and fast, no collision, automatic edge finding, reducing sheet waste.

Intelligent Control System

CypCut plane cutting software is a set of software specially developed for the deep customization of the laser cutting industry, easy to use, rich in functions, suitable for various processing occasions.

Intelligent Central Control Lubrication

The time and frequency of lubrication can be adjusted through the central control system, and comprehensive multi-point lubrication for guide rails, sliders, screws, racks, etc., and automatic return and collection of waste lubricating fluid.

Cutting Sample

Model | YM-FH 3015T | YM-FH 4015T | YM-FH 6015T | YM-FH 4020T | YM-FH 6020T | YM-FH 6025T | YM-FH 8025T |

Laser Power | 1000w~6000w | ||||||

Accuracy Of Positioning | ±0.05mm | ||||||

Repeat Repositioning Accuracy | ±0.03mm | ||||||

Maximum Speed | 100m/min | 120m/min | |||||

Tube Size Range | φ10-φ225mm,□10- □225mm | ||||||