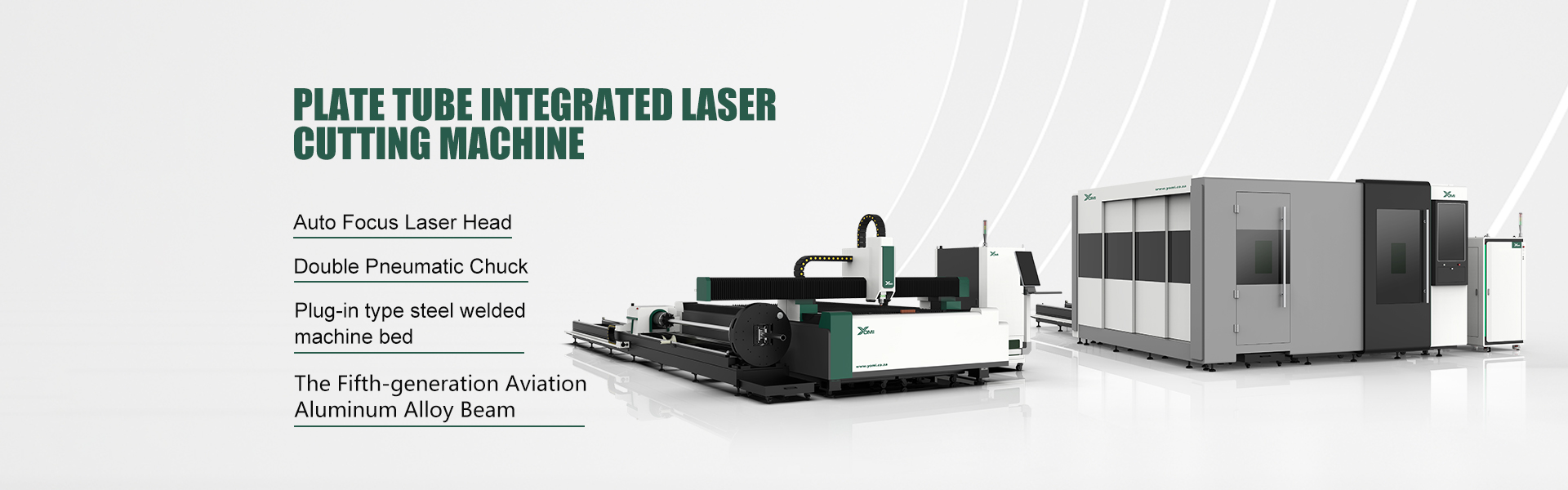

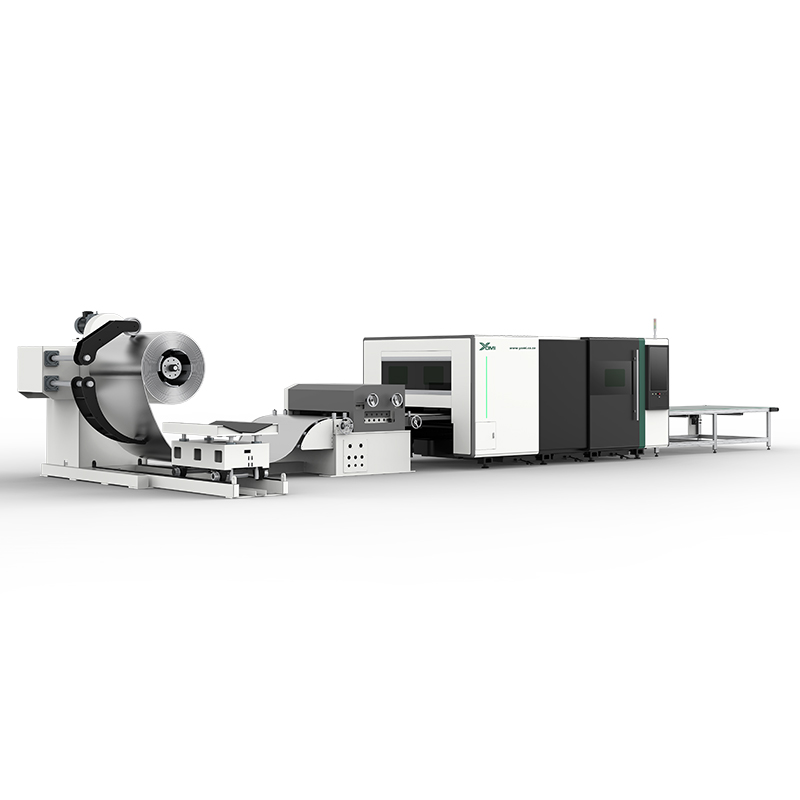

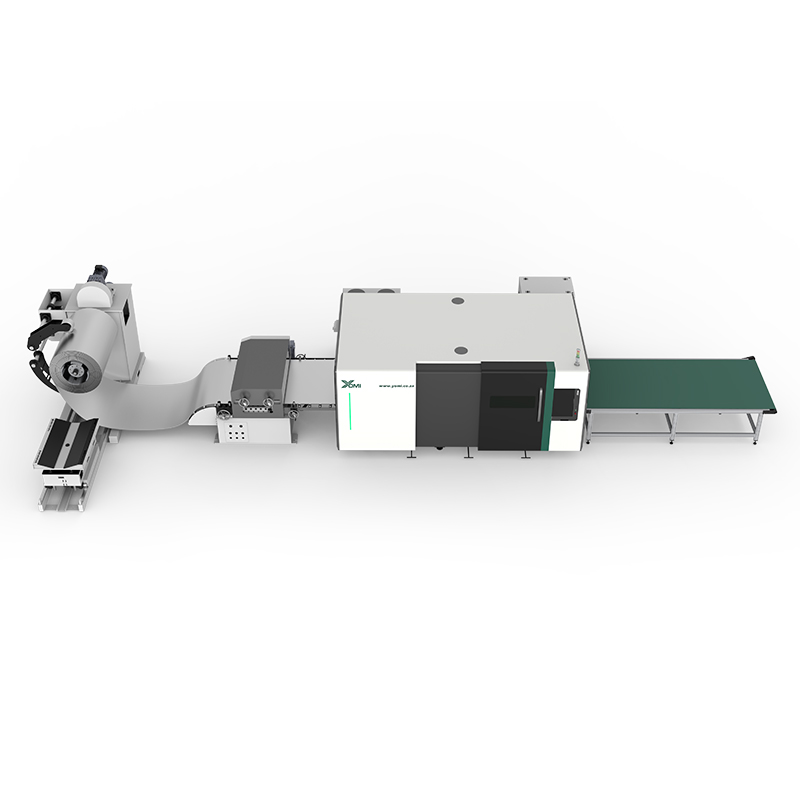

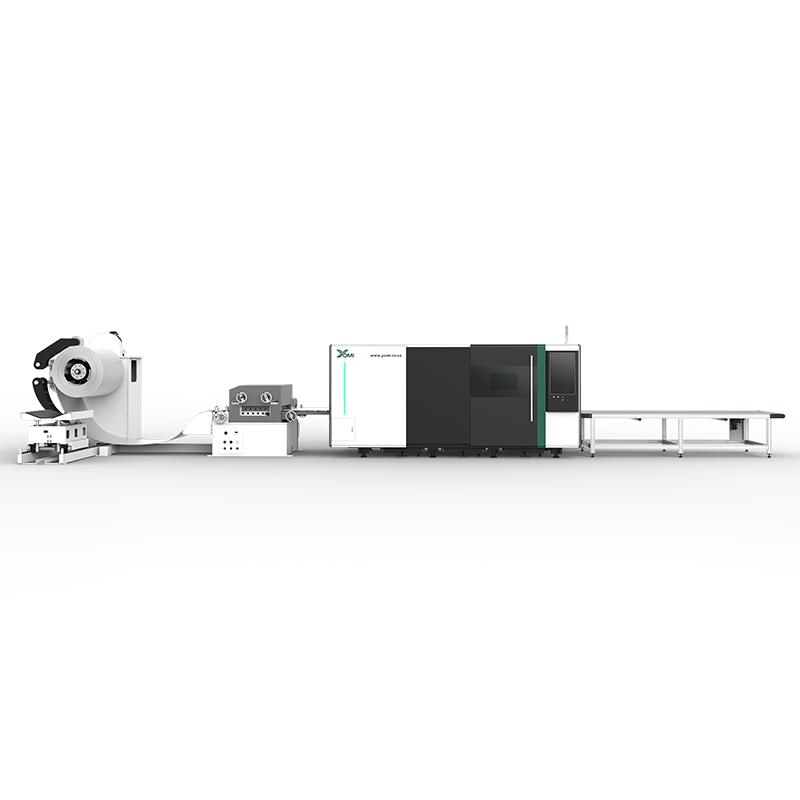

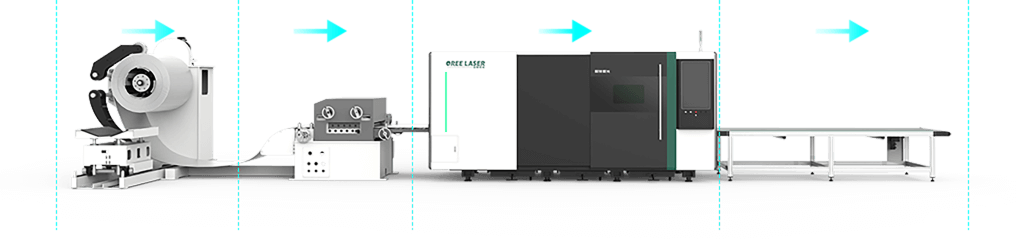

Coil steel laser flexible production line

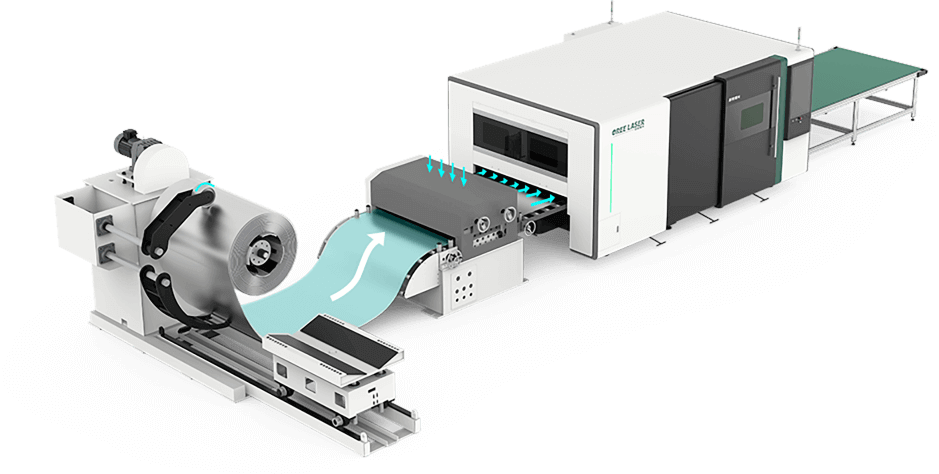

Large enclosure design

Isolating the work area and keeping the cutting area closed can ensure the safety of the operator while preventing the leakage of dust generated by the cutting and ensure the cleanliness of the work area.

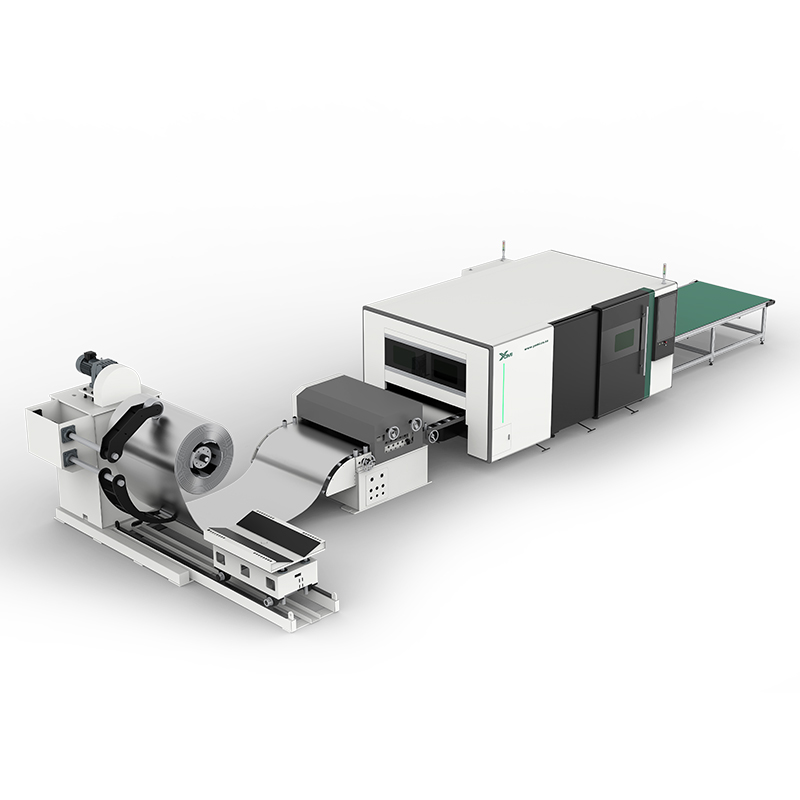

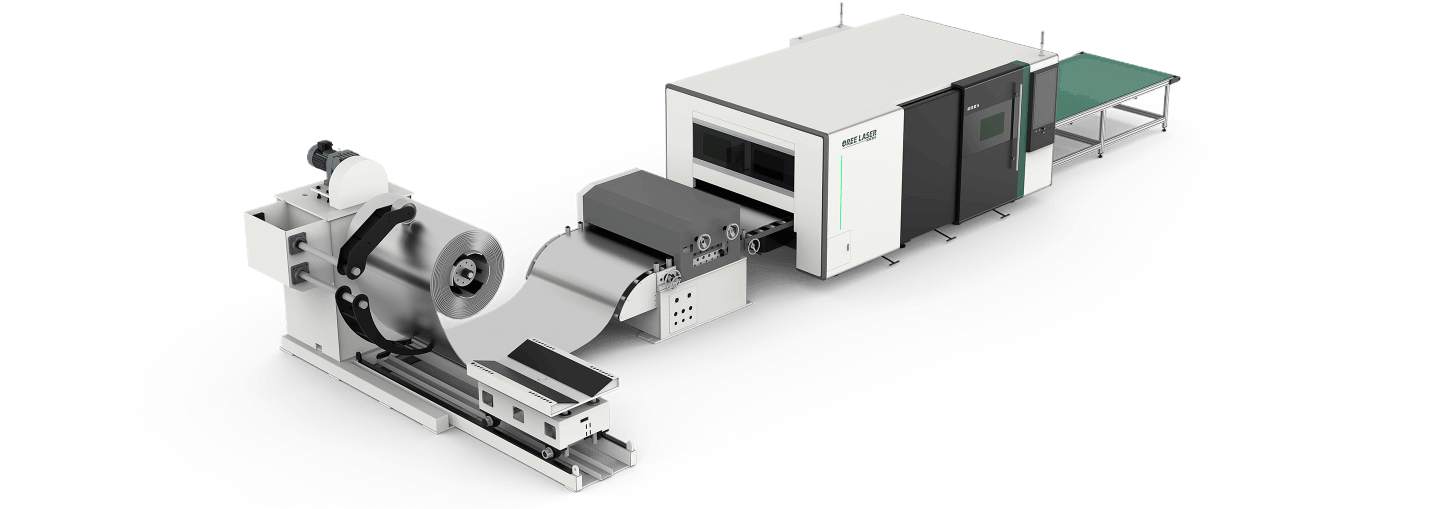

Stress annealed heavy material rack

Cantilever structure, stress annealing, high load-bearing frame, stable operation. Frequency conversion control, stable feeding material, hydraulic expansion, flexible operation. The material rack adopts hydraulic expansion and comes with a feeding trolley for flexible operation.

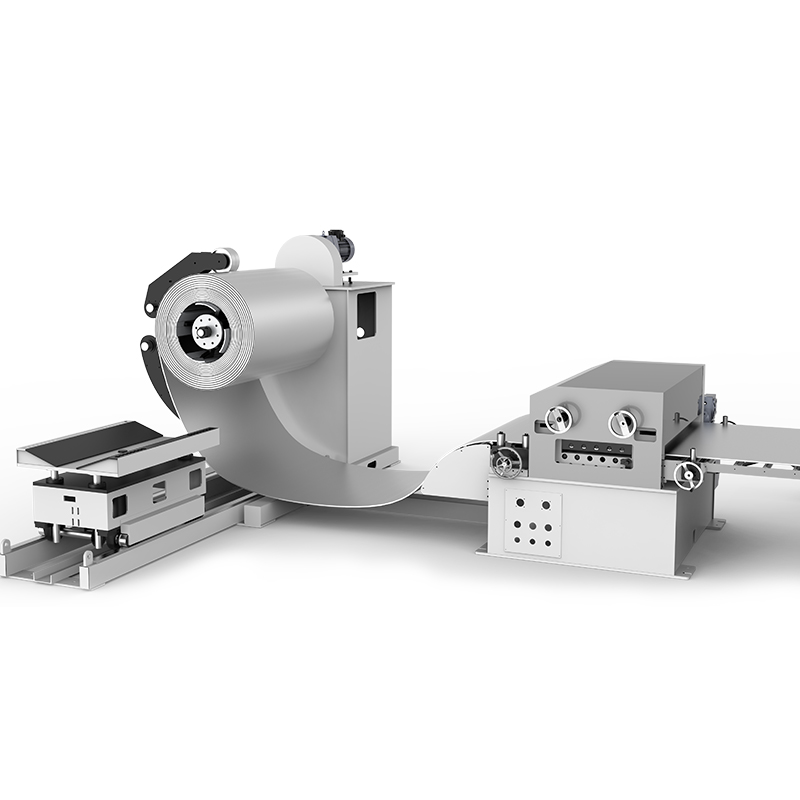

“Double”mode high efficiency leveling machine

Thickened electroplated bearing steel, durable and wear-resistant; turbine synchronization, worm adjustment; manual and electric dual mode, gear transmission; self-equipped pressure roller, high-quality and powerful leveling.

Servo precision feeding device

Servo motor drive, follow-up roller support, reduce metal sheet slip and curling.

Automatic assembly line

It can realize the uncoiling, leveling and cutting of bare roll materials in one go, saving labor and efficient production.

Model | R3015 | R4015 | R6015 |

Laser Output Power | 1000w-3000w | ||

Max Processing Range | 3050mm*1530mm | 4050mm*1530mm | 6050mm*1530mm |

Positioning Accuracy | ±0.03mm | ||

Repeat Positioning | ±0.02mm | ||

Max Movement Speed | 80m/min | ||

Max Acceleration | 1G | ||