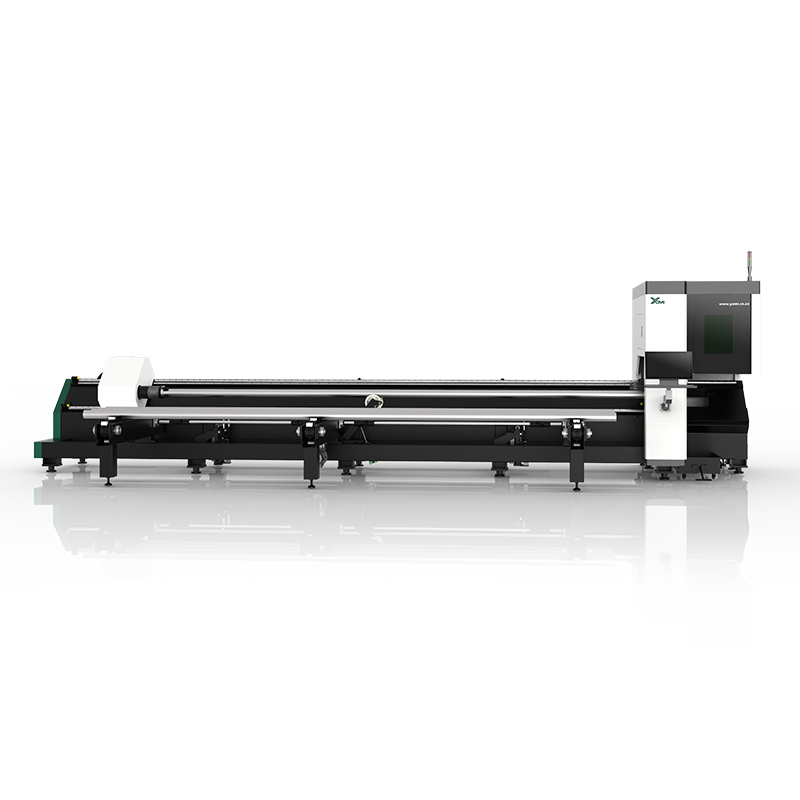

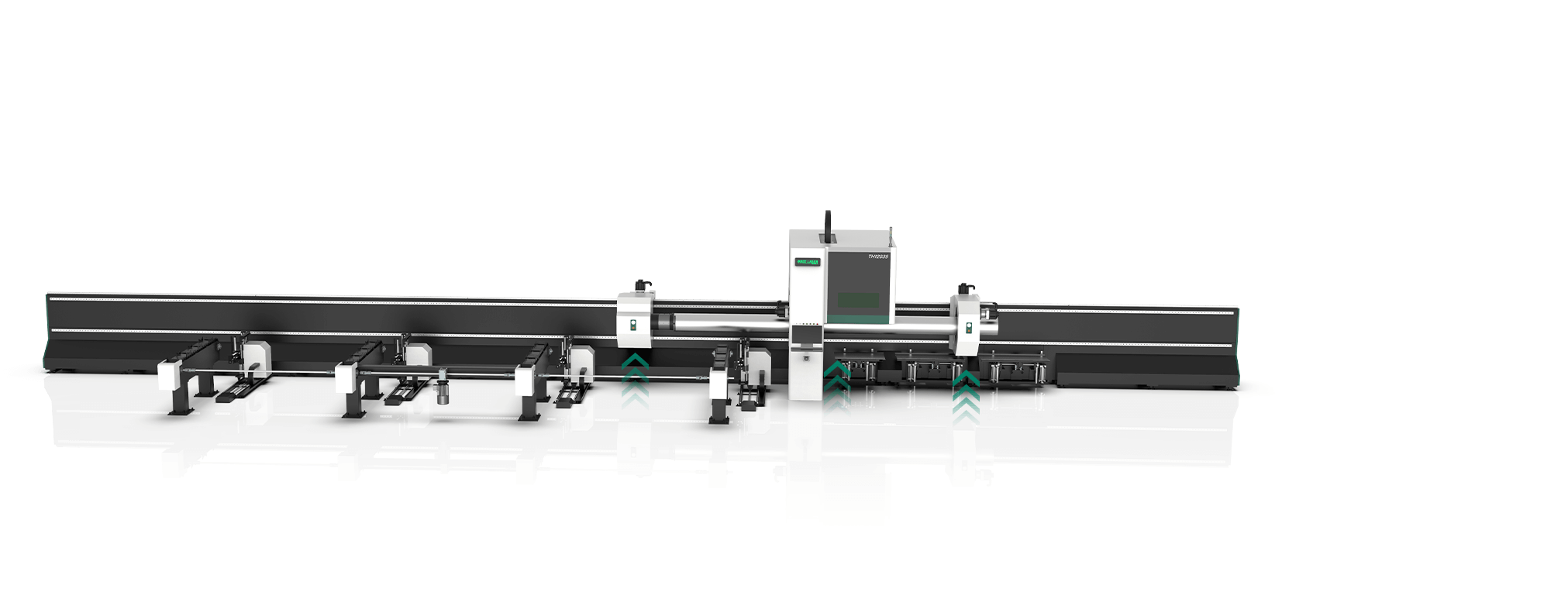

Side-mounted high-efficiency laser pipe cutting machine

Automatic pneumatic chuck

Fully automatic pneumatic chuck, stable and efficient. One key to open the clamp, automatic centering, speed is 3 times of electric chuck. Pneumatic open clamp, large clamping force and adjustable strength, heavy tubes do not loosen and do not slip, light tubes do not deform, to ensure cutting accuracy.

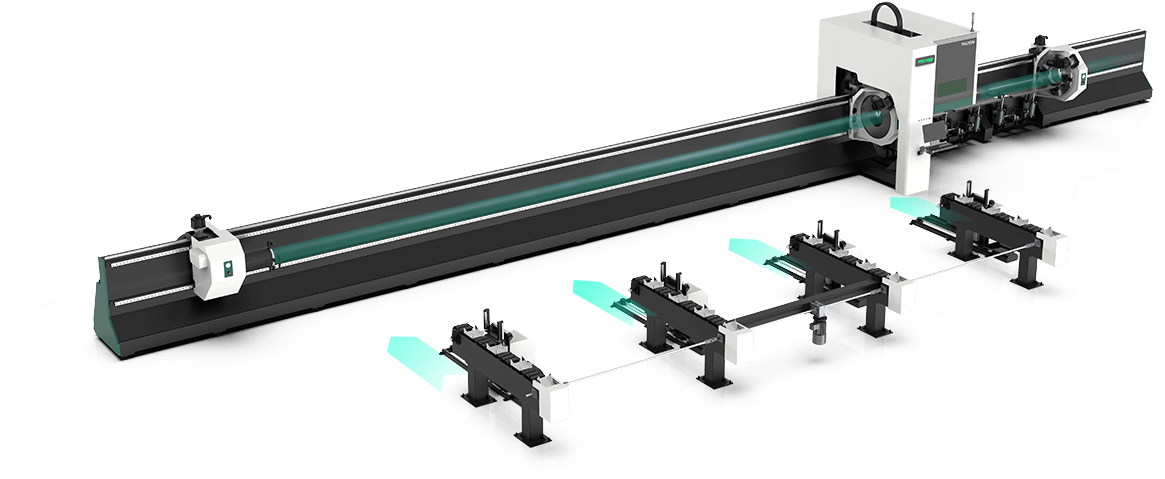

Zero tail material cutting process

Three chuck commutation cutting, super heavy pipe stable clamping; realize heavy pipe infinitely zero tail material cutting, improve material utilization rate.

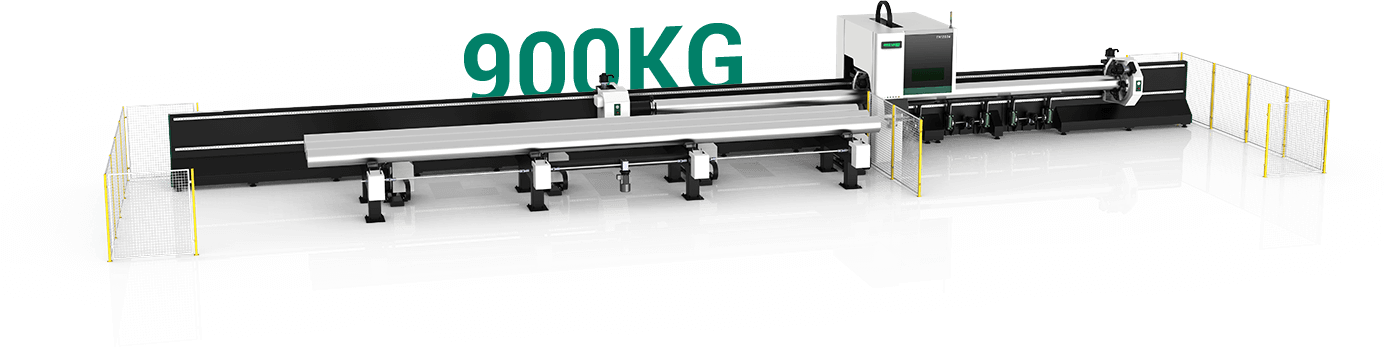

Heavy tubes and profiles, cutting is a breeze

Stronger single pipe load capacity, maximum load capacity up to 1200kg

Round tube diameter range 10-350 mm, tube length 12000 mm.

Channels steel, angles steel, I-beams steel and other profiles are fully supported; extra-long tube cutting can be realized, 12 meters on 6 meters off (expandable).

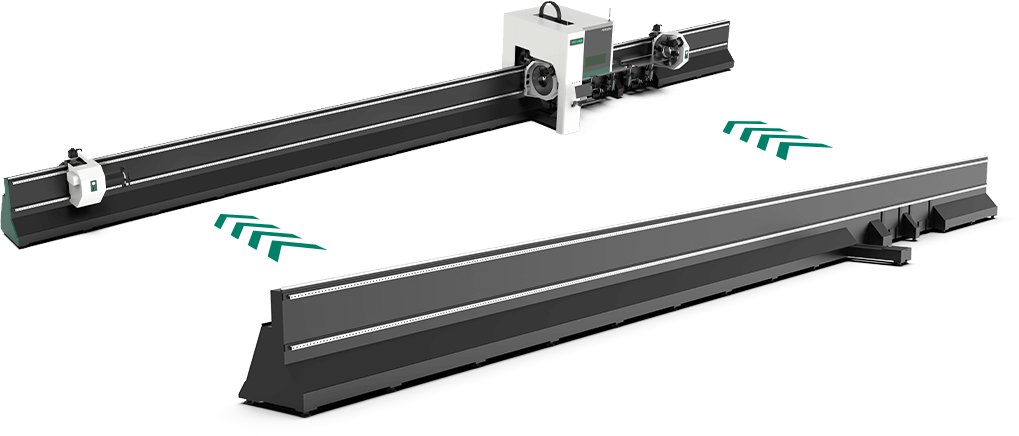

Integral profile welded bed

The machine adopts the welded structure of the whole profile verified by finite element analysis. The machine is annealed to eliminate internal stress and then finished to improve the rigidity and stability of the machine and to provide a longer service life.

Automatic loading system

Standard semi-automatic feeding, more safe, convenient, reliable, stable and efficient.

Simple feeding operation, only need to place multiple tubes on the conveyor belt to achieve automatic feeding.

Self-developed system

Comes with pipe graphic library data, no additional programming operations, efficient and time-saving, can automatically generate reports and processing records, more convenient management; anisotropic pipe graphics can be expanded, planarized path real-time display more intuitive.

Model | YM-TE |

Laser power | 3000w~12000w |

Effective cutting diameter of round tube | Φ20-Φ350mm |

Effective cutting diameter of square tube | □20-□350mm |

Positioning accuracy | ±0.05mm |

Chuck maximum speed | 60r/min |

Maximum acceleration | 0.6G |