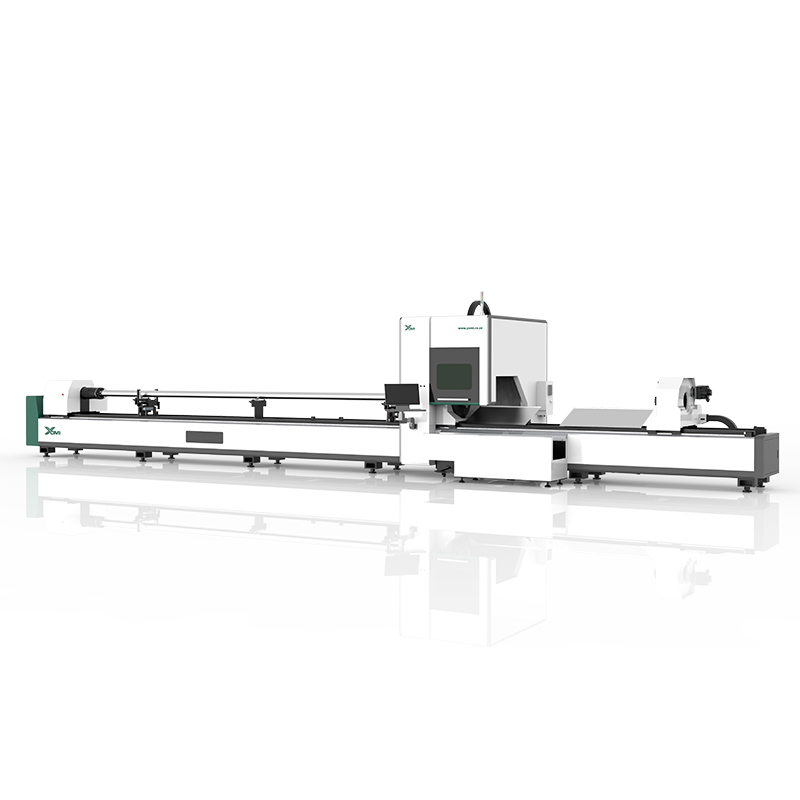

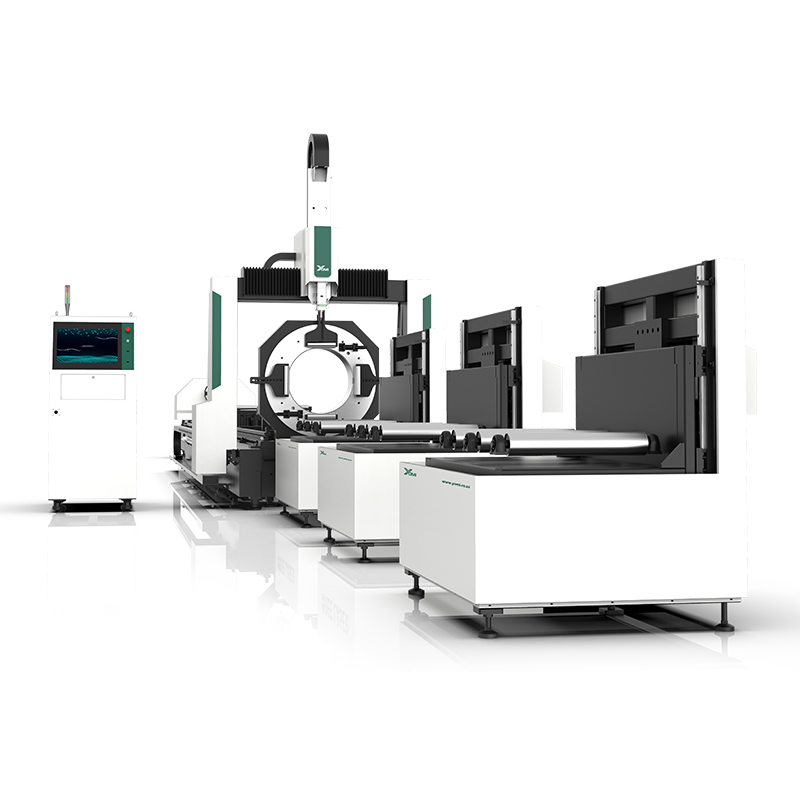

Three-chuck tube fiber laser cutting machine

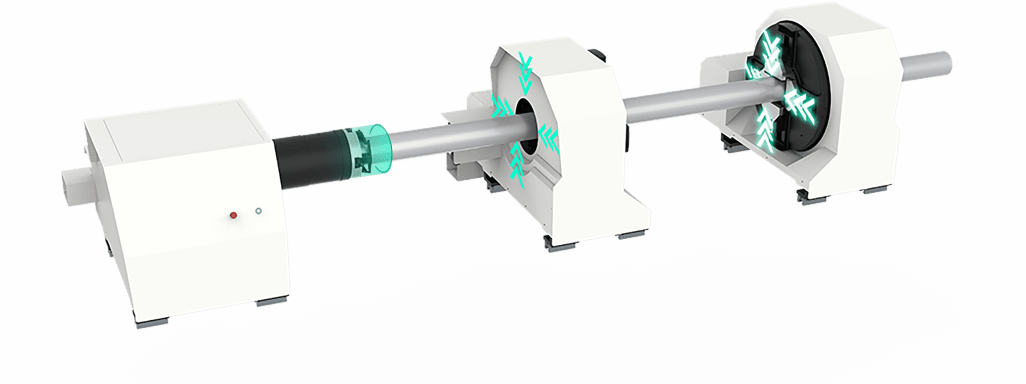

Three chucks clamping & zero tail materials

Three chucks clamping & zero tail materials Innovative three-chuck clamping technology, the chuck clamping force is adaptive to the pipe, realize accurately clamped; The casting integrated chuck base improves the overall stability of the chuck and achieves high-precision positioning cutting; The three chucks operate in coordination, after the chuck through the middle chuck internal cutting operation.

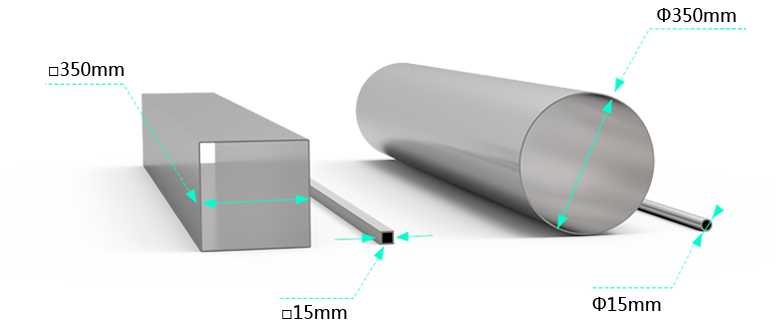

Wide range of pipe cutting

It supports the processing of 12000mm ultra-long whole workpiece, channel steel, angle steel, I-beam and other profiles, and the maximum load-bearing capacity of a single pipe is 900KG.

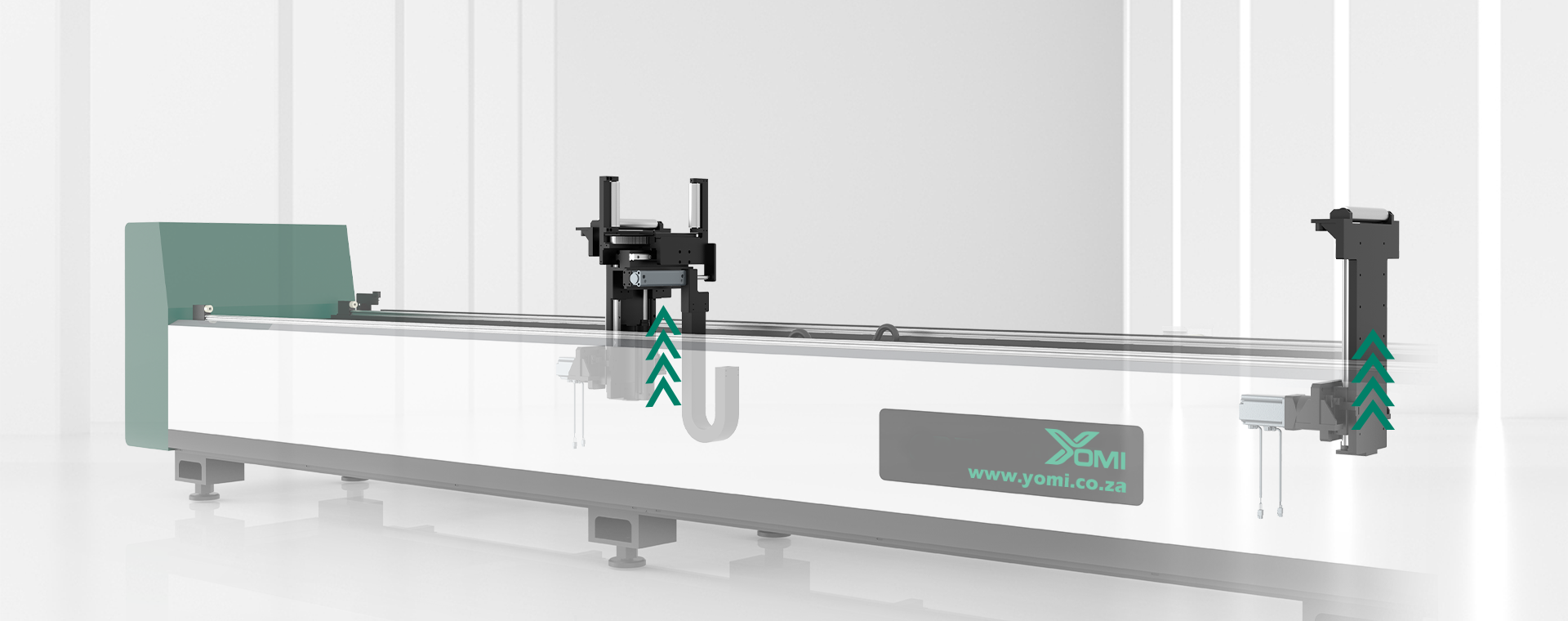

Double-sided follow-up support device

It can reduce processing errors, ensure uniform force on the entire metal pipe, and improve cutting accuracy. Real-time feeding to prevent the reduction of cutting accuracy due to pipe distortion.

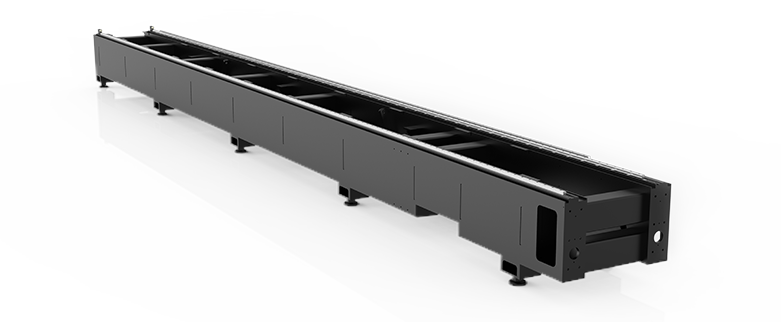

Integrated frame bed design

The integrated processing technology of high-precision gantry machine tool, through furnace annealing and aging treatment, the stability and cutting precision of the bed are greatly improved and the service life of the bed is prolonged.

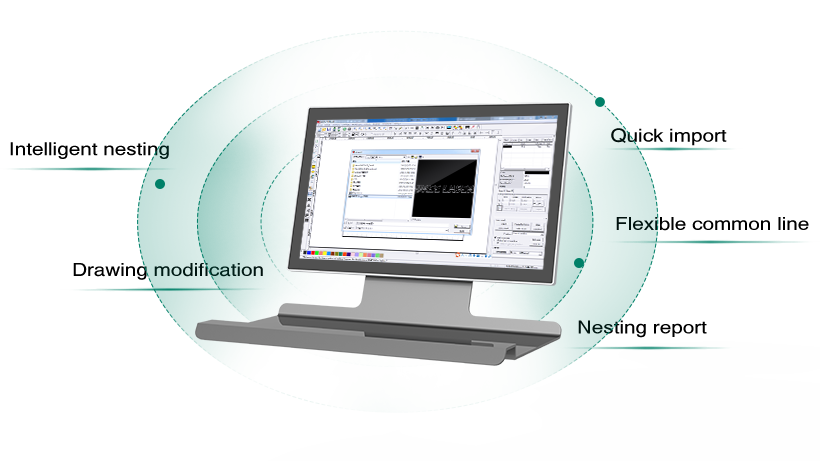

3D tube nesting software TubesT, meet your production needs

TubesT is a 3D tube nesting software for the TS series. From parts drawing and modification, full type compensation, strategic nesting to report generation, using TubesT will meet and exceed your production needs.

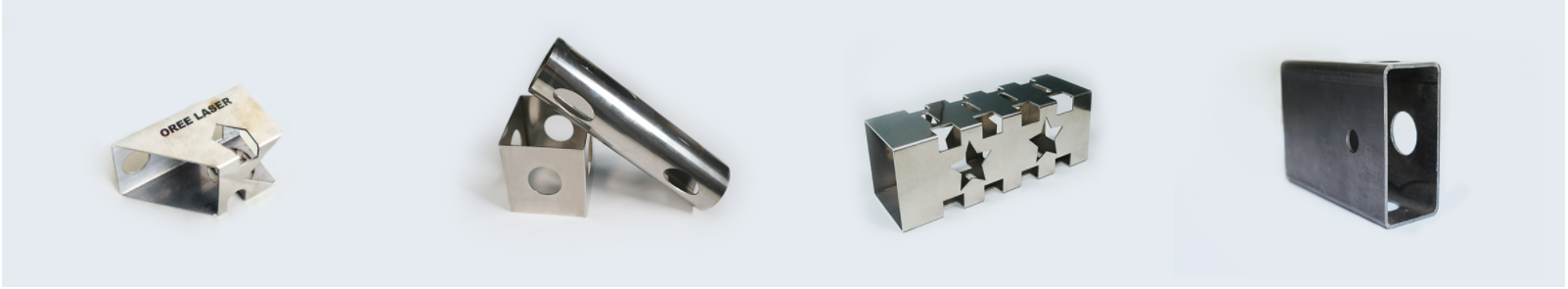

Cutting Sample

Model | TS12035 | TS12020 | TS6020 |

Laser Output Power | 1000W~6000W | ||

Diameter Of Round Tube | φ15-350mm | φ15-230mm | |

Side length Of Square Tube | □15-350mm | □15-230mm | |

Positioning Accuracy | ±0.05mm | ||

Repeat Positioning Accuracy | ±0.05mm | ||

Maximum Speed Of Movement | 80m/min | 110m/min | |

Maximum Acceleration | 0.8G | 1.5G | |